|

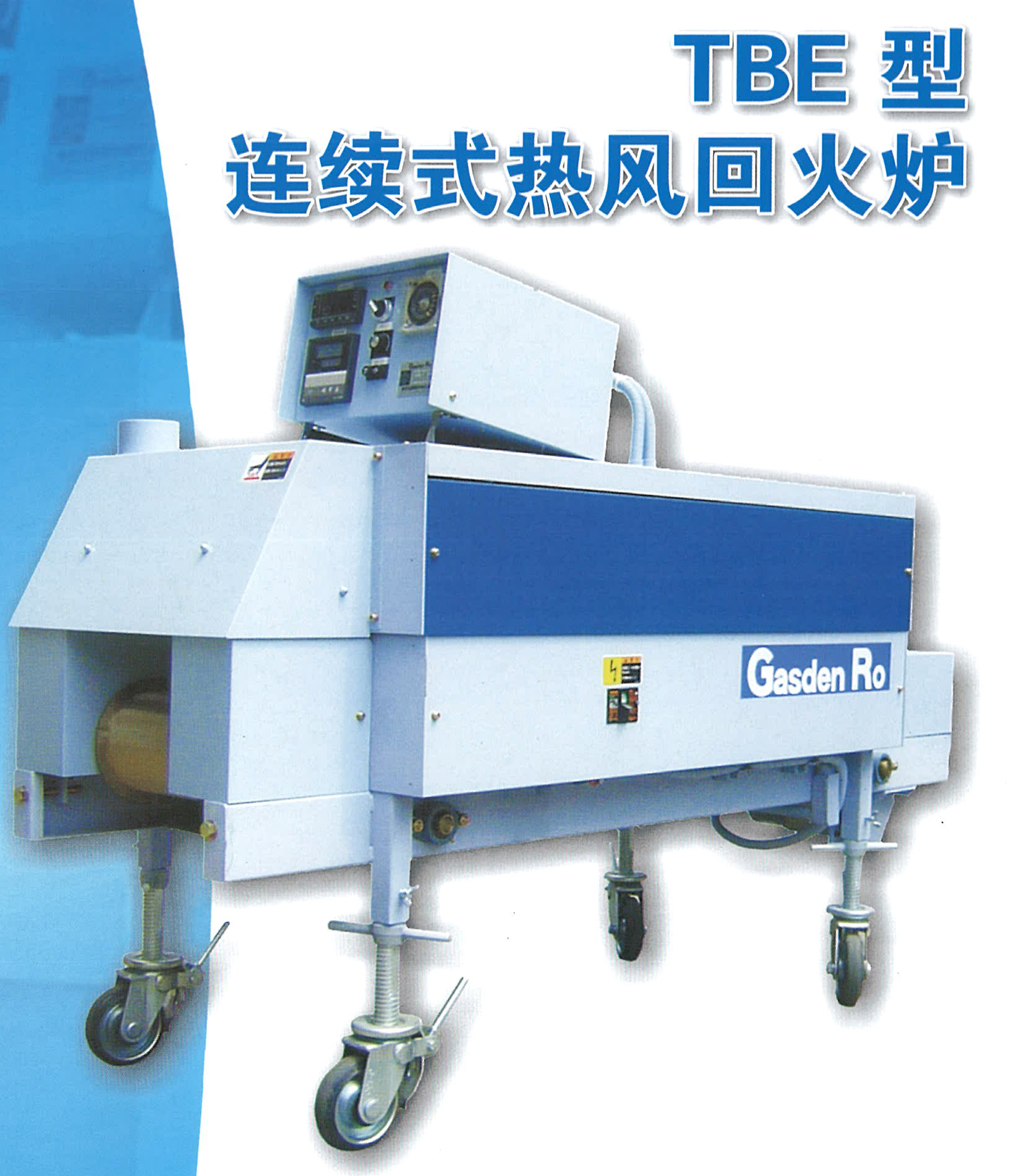

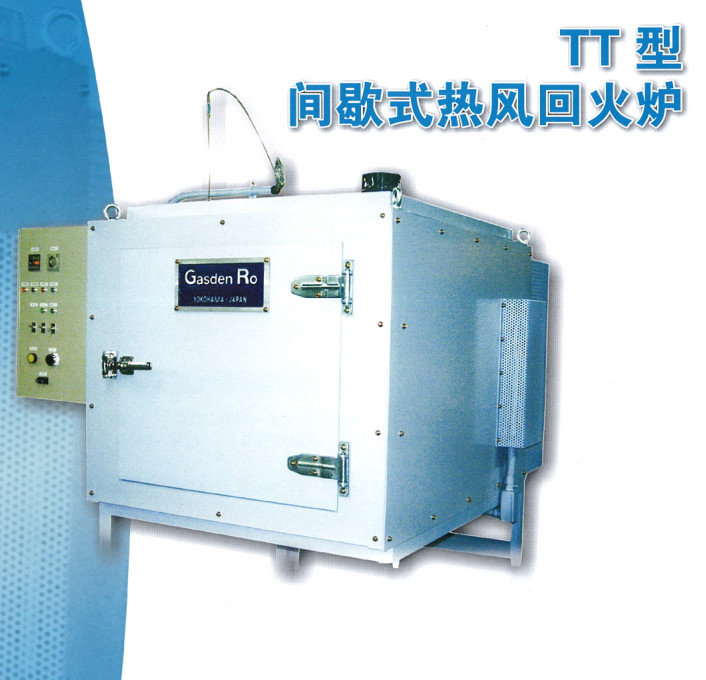

The heat treatment equipment mainly includes: far infrared drying furnace (gas heating), near and medium infrared drying furnace, TBE continuous hot air tempering furnace, TC continuous hot air tempering furnace, TSO continuous austenitic isothermal quenching furnace (mesh belt conveying mode), TS continuous quenching, tempering furnace (carburizing and nitriding mode/acidless quenching mode), TT batch hot air tempering furnace.

|

|

Uses: coil spring tempering, leaf spring low-temperature return, bluing treatment, drying and baking

特點(diǎn)

.Digital automatic temperature control;

.Mesh belt type continuous conveying, constant processing time;

.The stirring fan fully stirs the hot air to reduce the temperature difference in the furnace and realize the uniform temperature treatment;

.It can be directly connected with the coil spring machine;

.The conveyor belt is extremely lightweight, and the heating tube is folded inside the furnace. The conveyor belt outside the furnace is equipped with a cover;

.The furnace body is equipped with casters, which can be moved freely;

.The furnace body can be adjusted up and down freely;

.The furnace cover can be opened freely, and the spot inspection in the furnace is convenient; |

|

|

|

Uses: tempering, baking, bluing, drying

特點(diǎn)

.The furnace uses a sleeve to isolate the flame, which avoids the direct heating of the treated products, and makes the furnace heat both heated through the thermal circulation of the stirring fan;

.The opening and closing mode of the door: (1) counterweight manual opening and closing (2) handle manual opening and closing (3) cylinder opening and closing;

.The power consumption can be reduced to a small extent;

.It can flexibly cope with the processing of multi-variety and small-batch workpieces, and the operation is simple; |

|

|

|

Uses: tempering, annealing and melt treatment, drying and baking, bluing treatment

特點(diǎn)

.Digital display automatic temperature control;

.The mesh belt conveyor belt is continuously fed, and the processing time is constant;

.The stirring fan fully stirs the hot air to reduce the temperature difference in the furnace and realize the uniform temperature treatment;

.The furnace is maintained under certain conditions, and the contact treatment is carried out;

.Modular heater is adopted, which is simple and convenient to maintain and replace; |

|

|

|

Uses: Leaf springs, small workpieces

特點(diǎn)

.Through the temperature adjustment of 2-5 points of temperature detection in the furnace, the temperature distribution of each area in the furnace is good;

.Near the discharge slideway, there is a protective device to prevent the gas intrusion generated by the salt bath;

.Through the conveyor belt, the workpiece with complex shape can also be processed continuously;

.The structure of the furnace is compact, and the consumption of atmosphere gas is reduced.

.The furnace body adopts a separable structure and adopts a modular group heater; Simple and convenient maintenance and replacement; |

|

|

|

Uses: bolts, bearings, leaf springs, disc springs, small screws, tap carburizing and nitriding treatment, and other small workpieces

特點(diǎn)

.The stirring fan is fully stirred to ensure that the workpiece in the furnace is carburized at a uniform temperature;

.Light insulation materials with less heat storage are used in the furnace to improve the energy-saving effect;

.Through the conveyor belt, the workpiece with complex shape can also be processed continuously;

.According to the different workpieces to be processed, you can choose the mesh belt conveying mode or the vibrating conveying mode. Effectively use the exhaust gas to preheat the workpiece and save energy;

|

|

|